EOP soft Interfaces

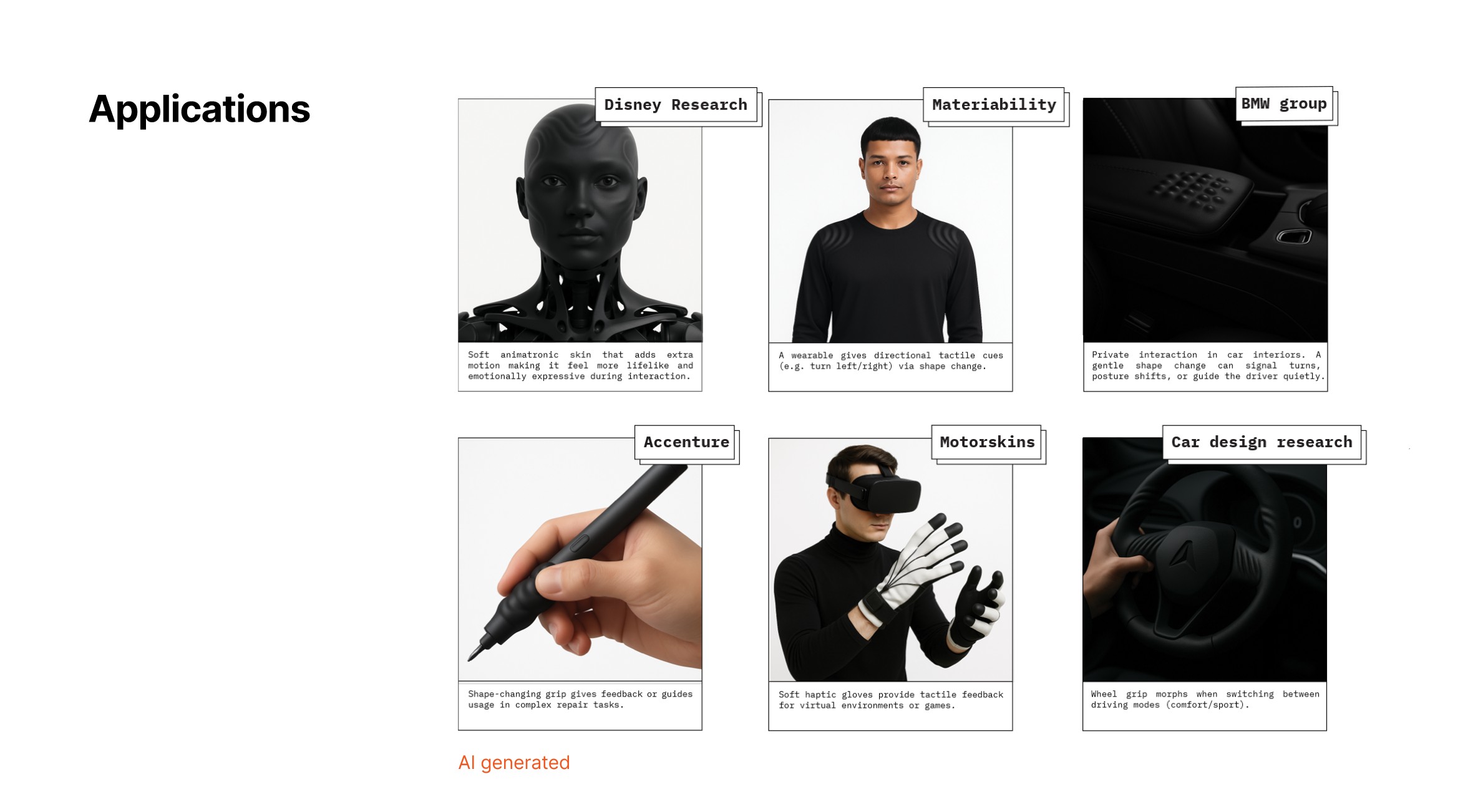

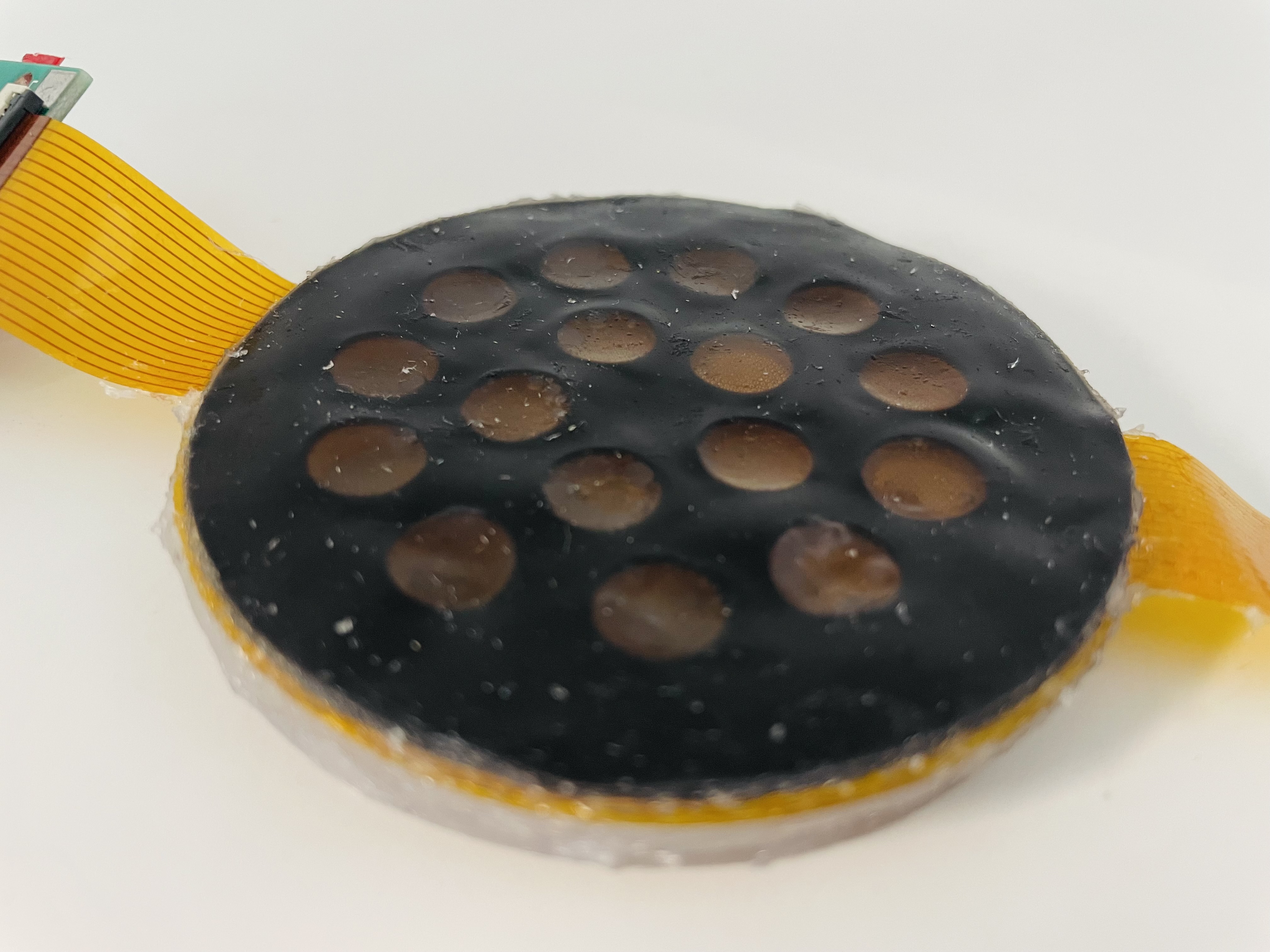

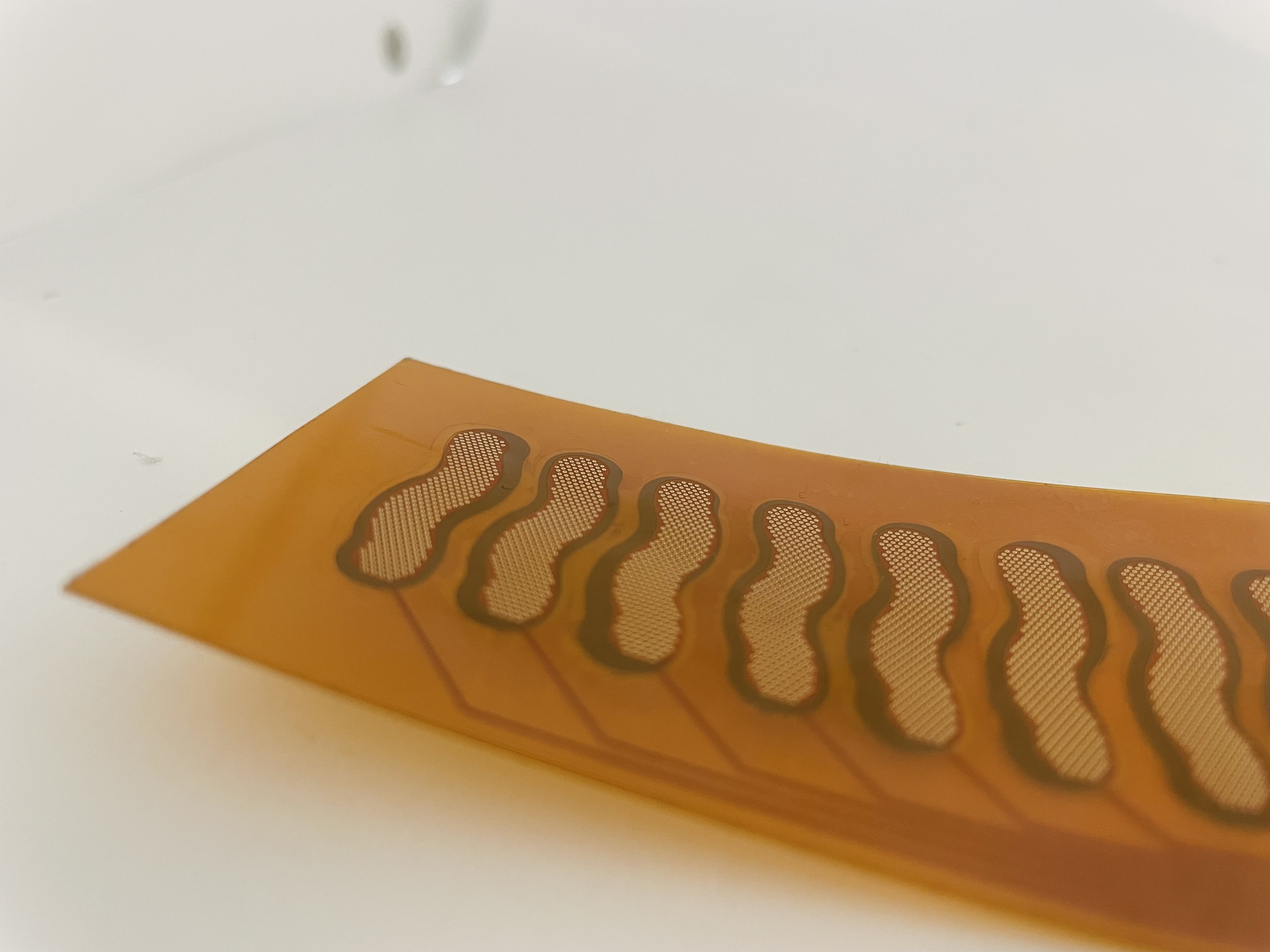

Using electroosmotic pumps (EOPs), these soft interfaces enable silent, high-resolution shape change in thin formats. The interfaces can sense and respond, offering subtle gestures that express presence, intent, or a state. Rather than replicating conventional controls, they invite new forms of interaction.

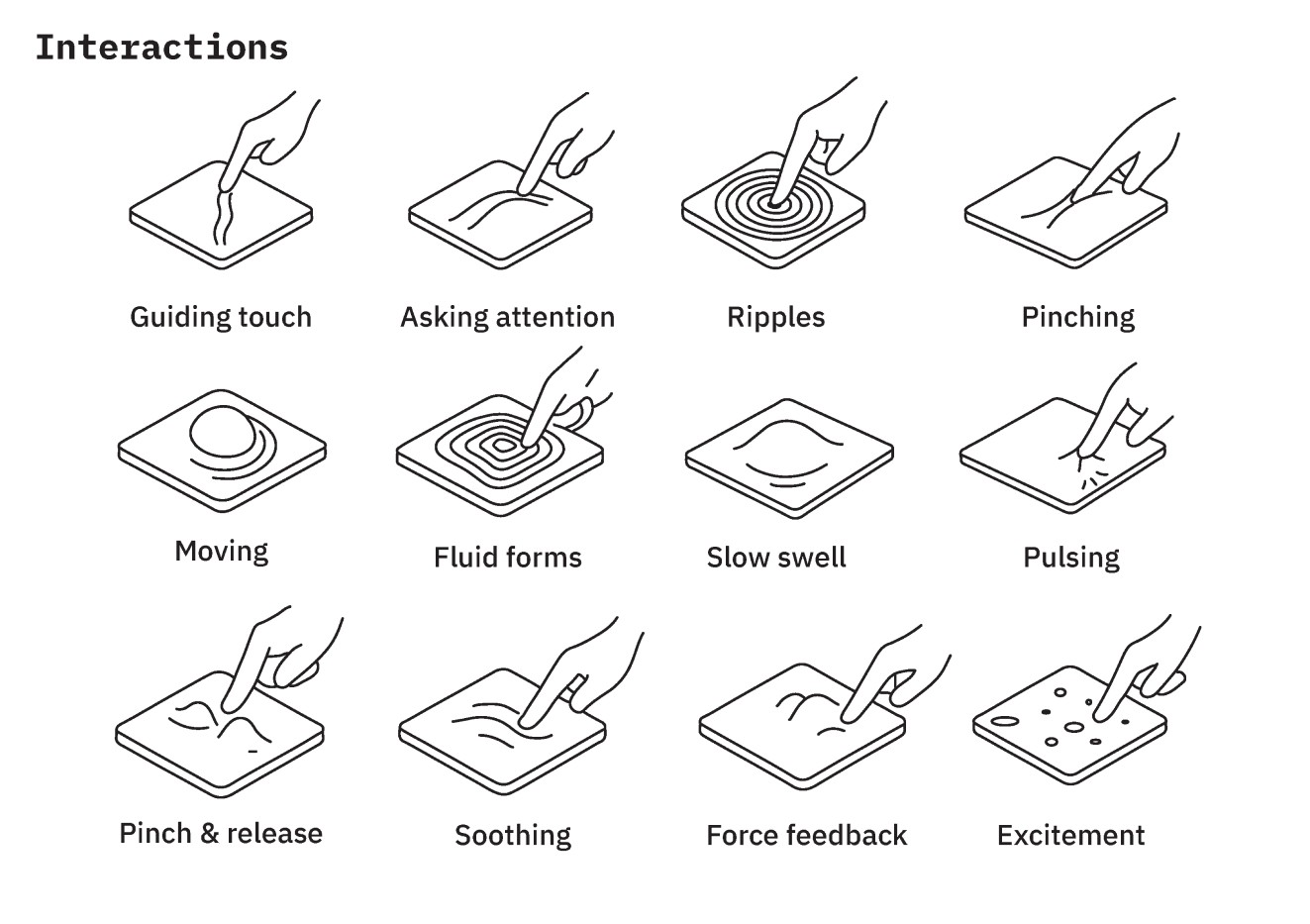

Interaction

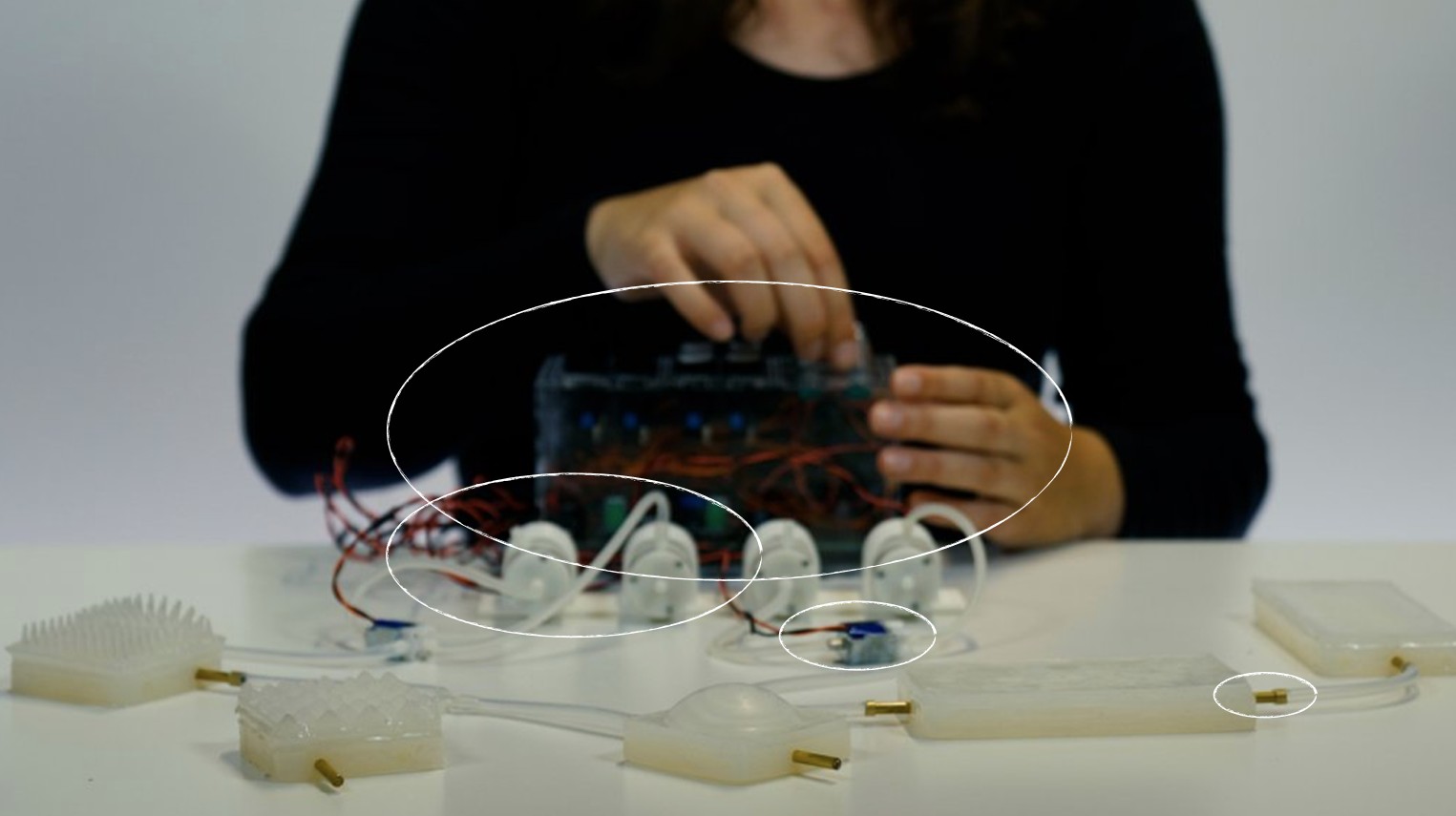

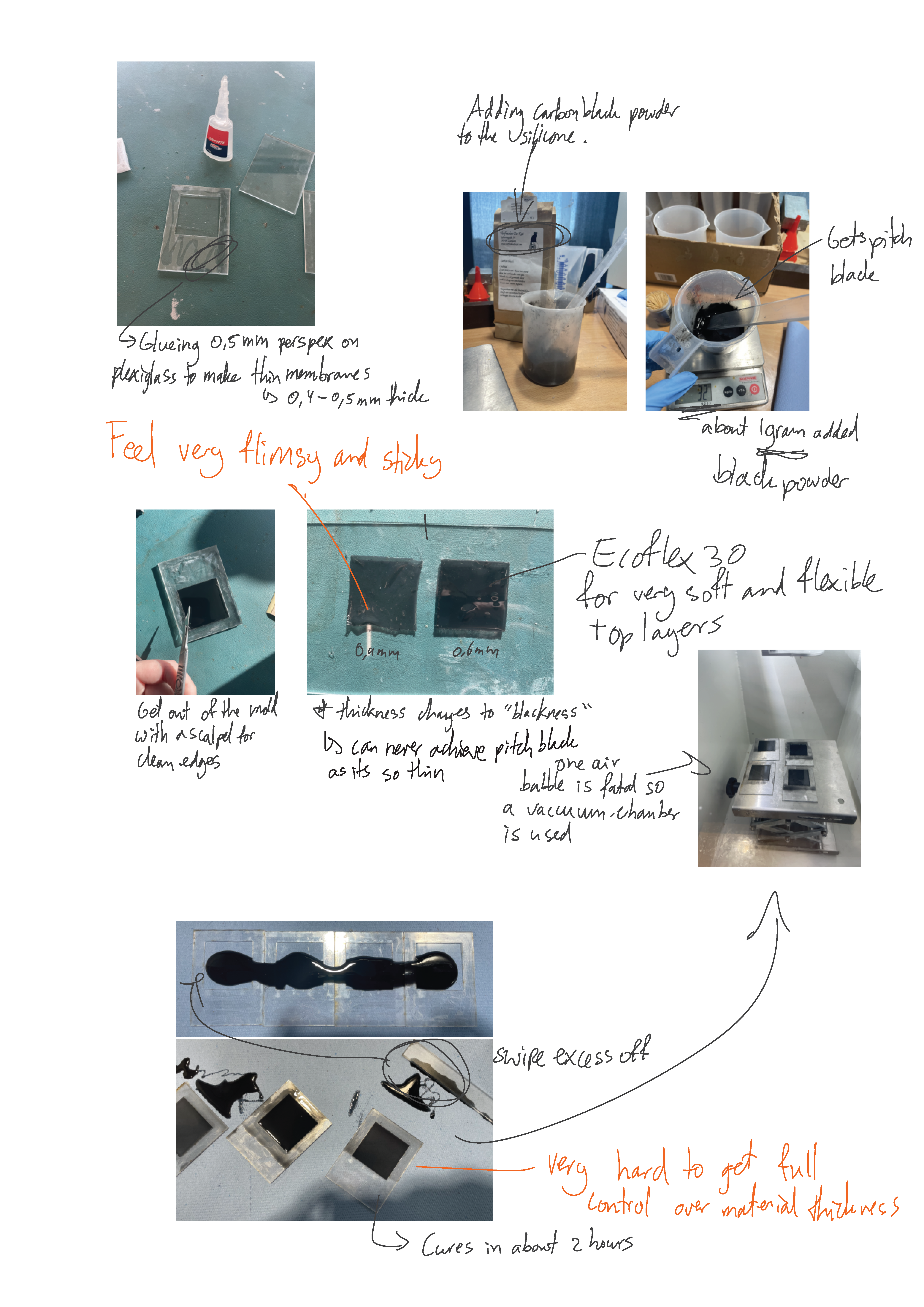

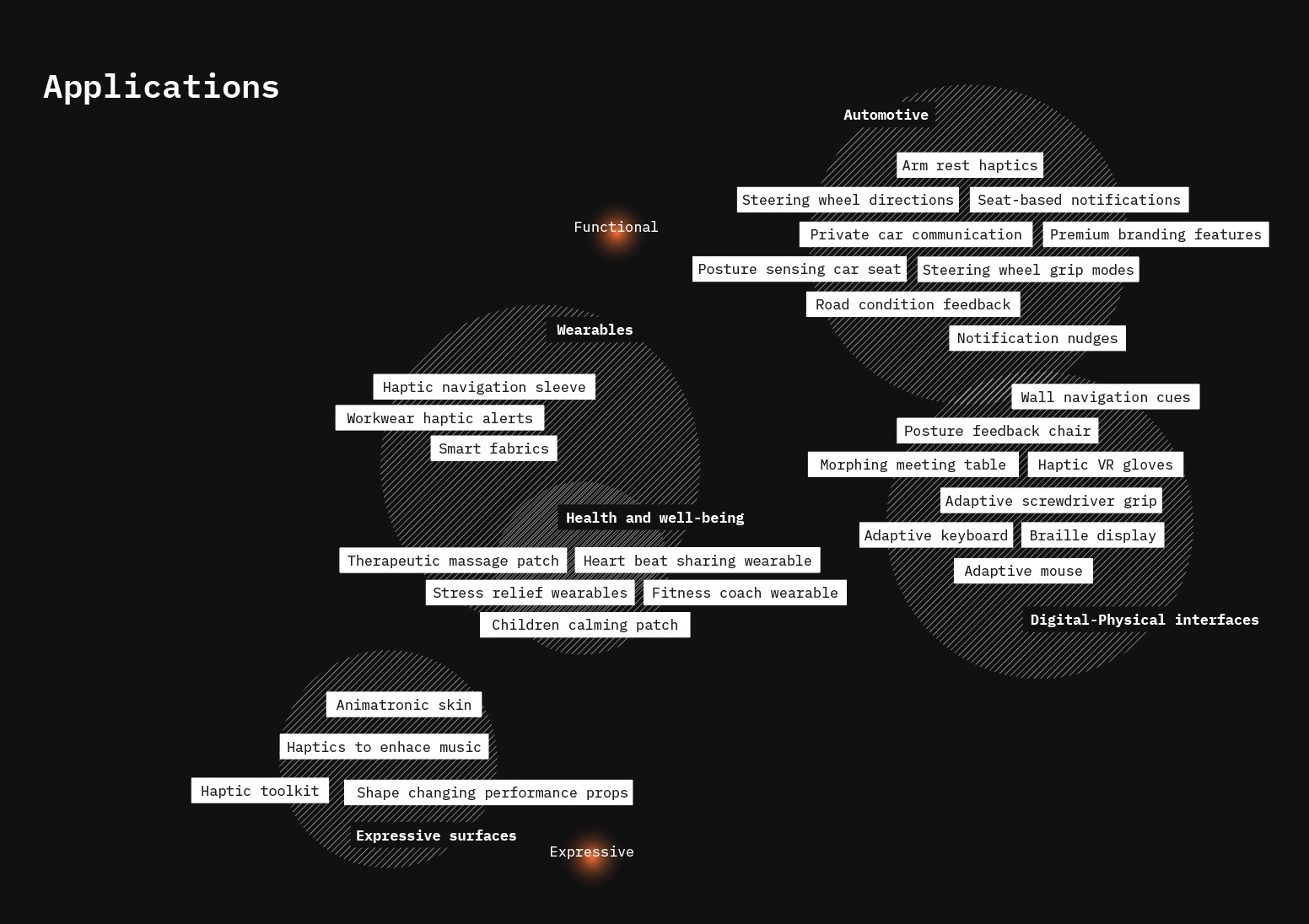

This thesis began with a vision of soft shape-changing interfaces, developed over the past two years and shared through the platform softinterfaces.com. It explores how technology can be expressed through form and integrated into the materials that shape our surroundings. Through experiments with magnetics, textiles, fluidics and pneumatics, I investigated ways for interfaces to communicate not only through sight and sound but through motion, deformation and touch. Reciprocity is the core of soft interaction; sensing and actuation must be designed as one, so the interface can feel and move in a single continuous conversation. In doing so, I became aware of how material dictates experience. The stickiness of silicone, the noise of air, and the bulk of tubing aren’t just technical frictions they influence how people engage with the interfaces, what they expect from it, and how it fits into everyday life.

Vision on interaction design

Why EOPs?

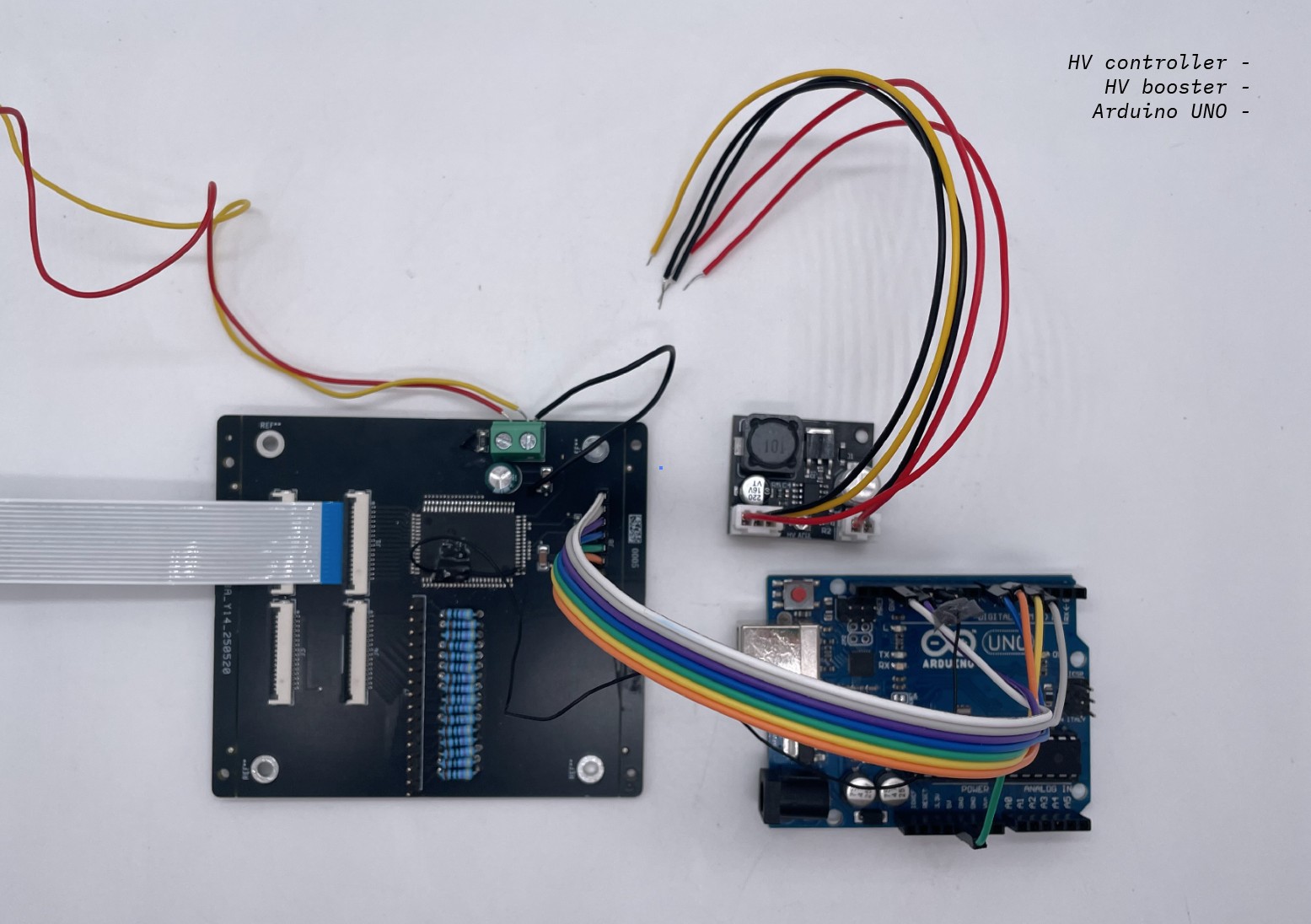

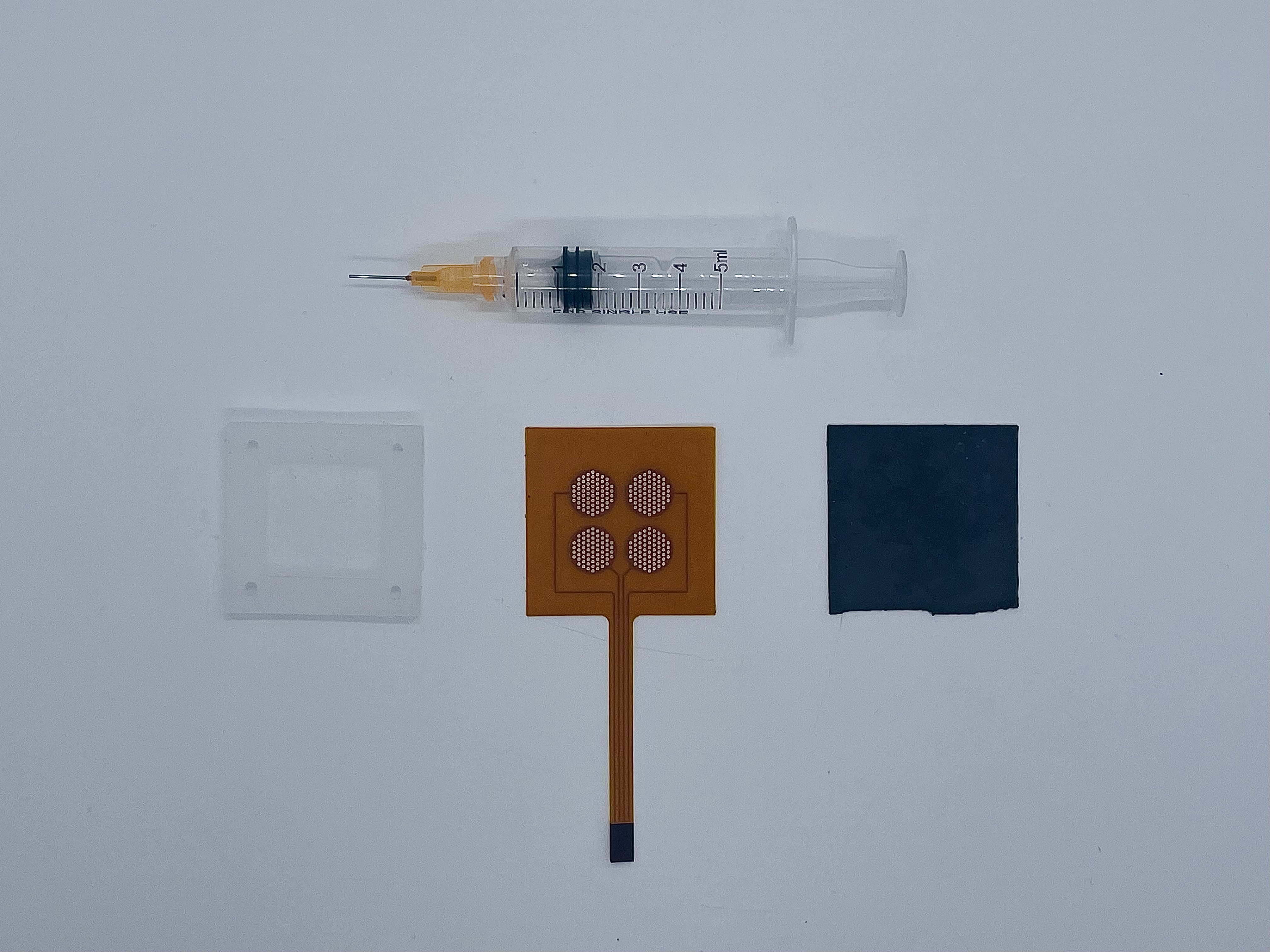

With the earlier soft interfaces I kept running into the same limitations: noise, rigidity, leakage, bulk and heavy power consumption. They were difficult to miniaturise, impractical to embed and still fell short of the subtle softness and interaction I envisioned. Creating thin, silent and high resolution actuation that disappears into surfaces demanded a different approach, which led me to electroosmotic pumps (EOPs), a scalable fluidic technology with no moving parts that supports both actuation and embedded sensing.

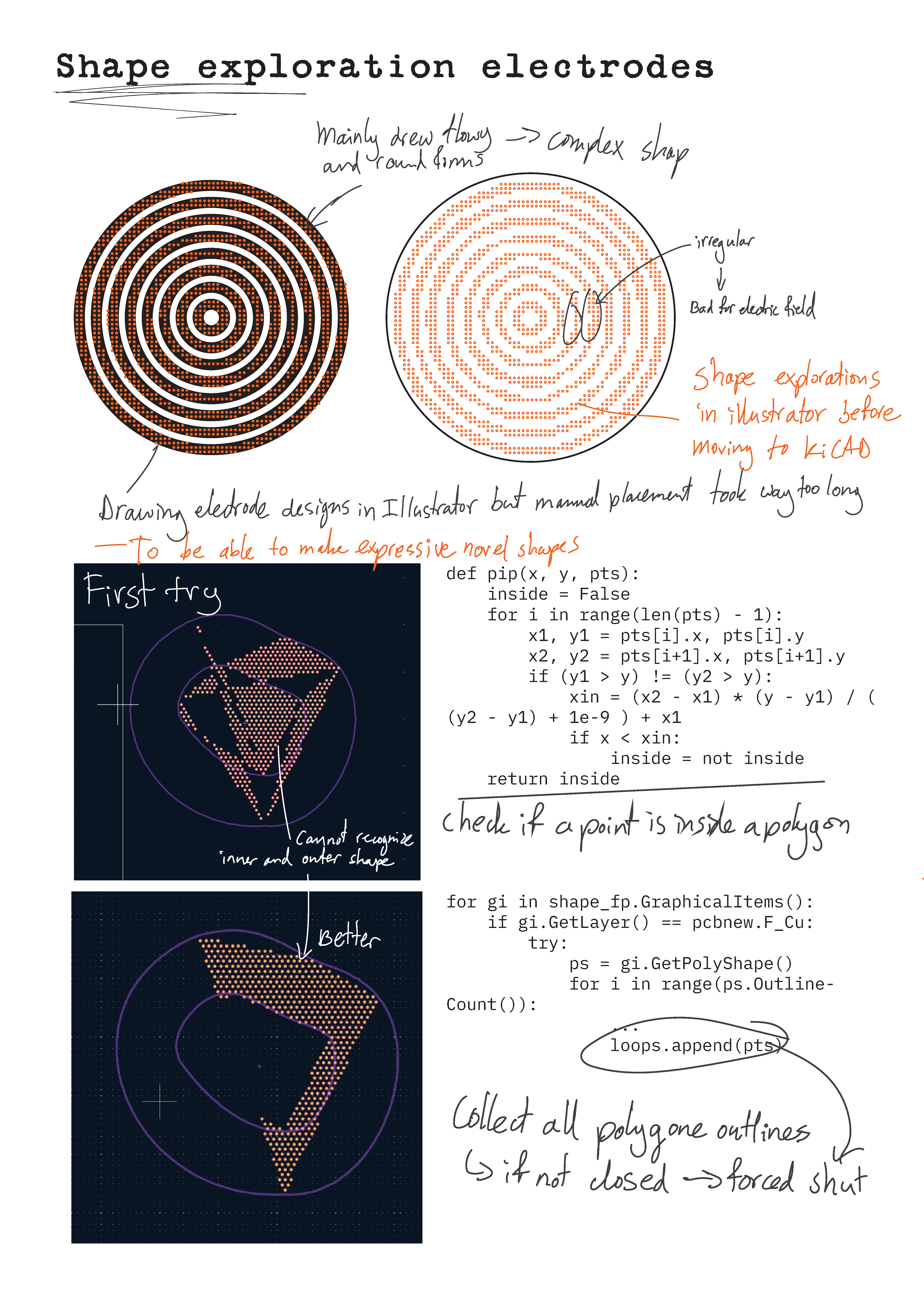

Expressivity

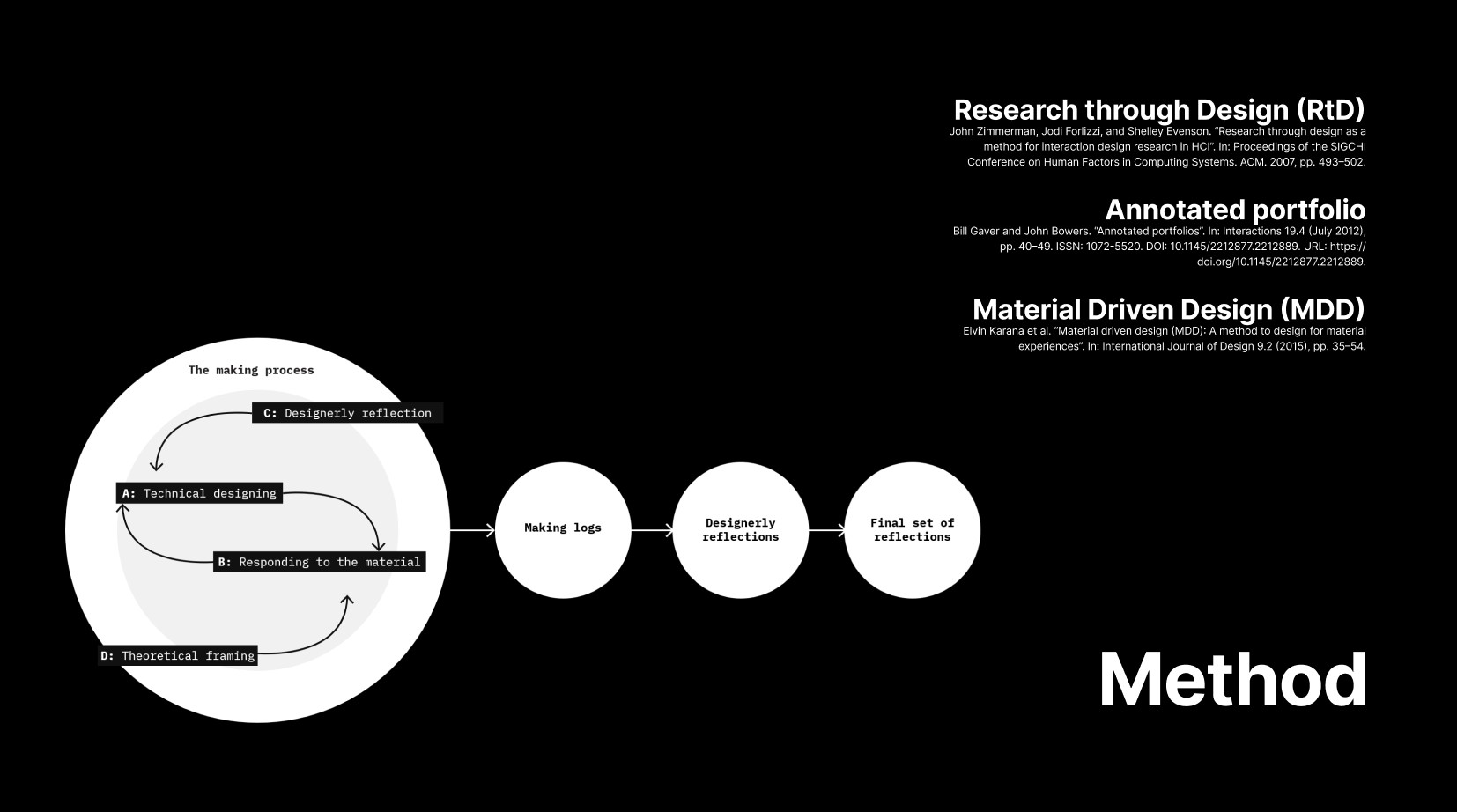

Method

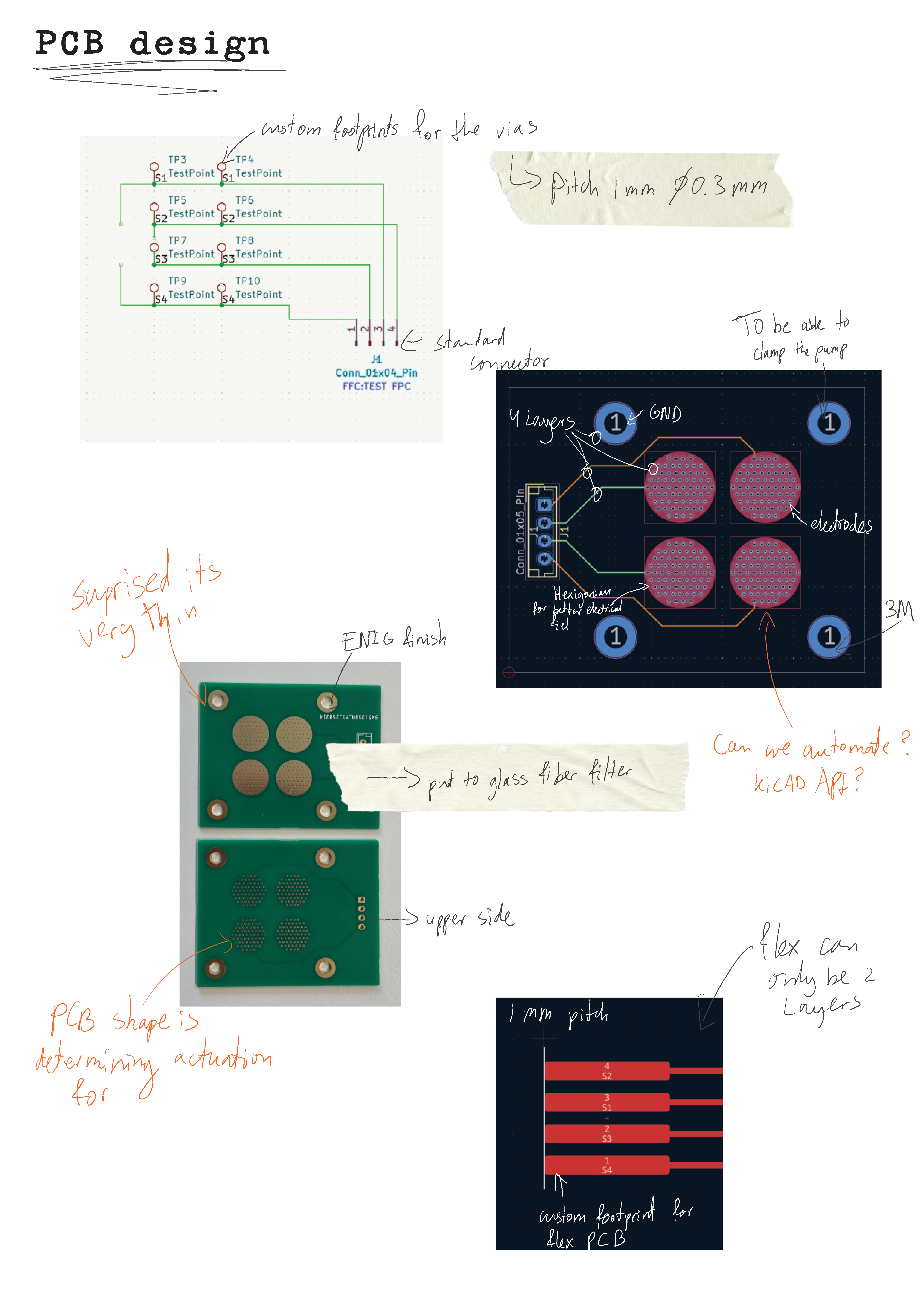

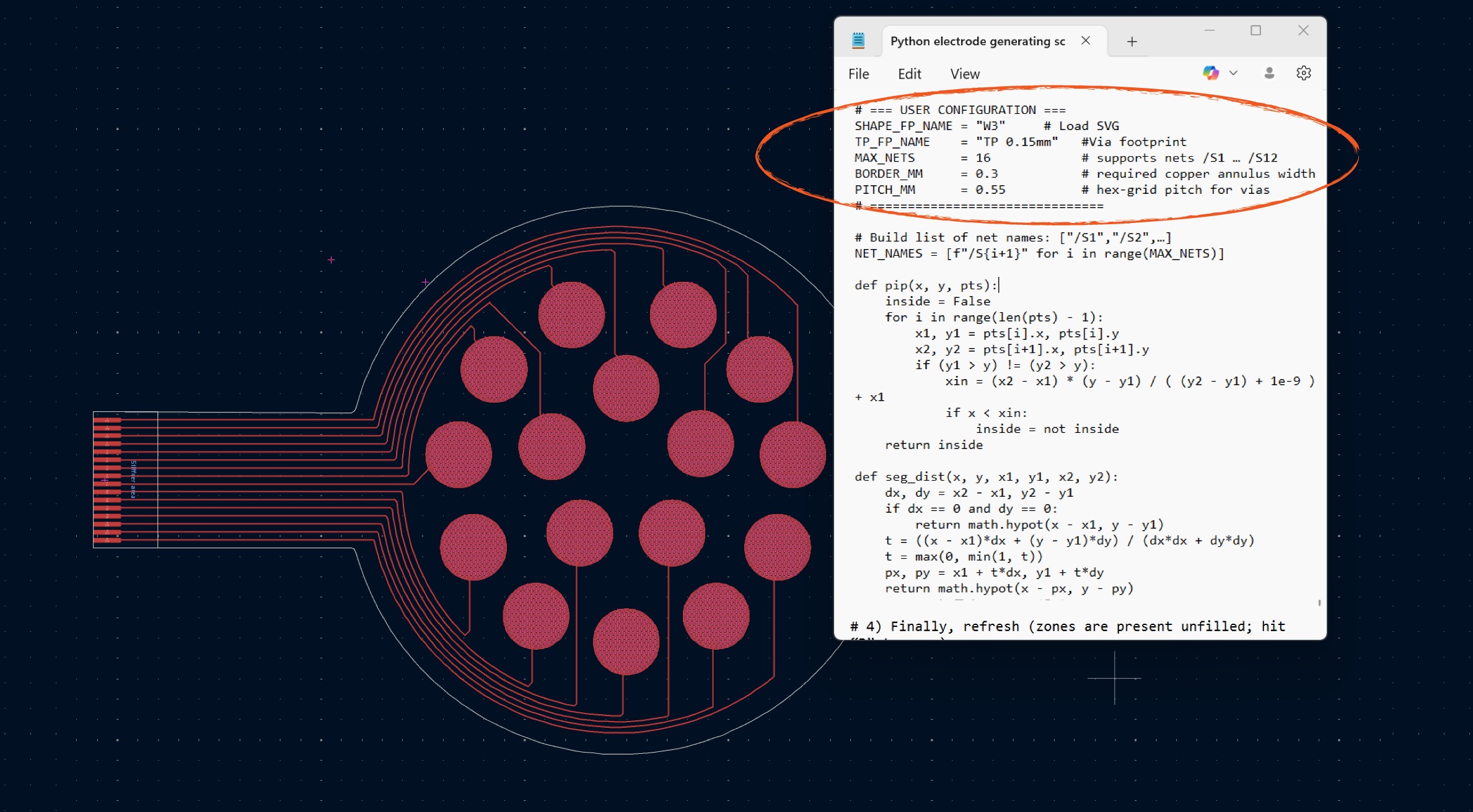

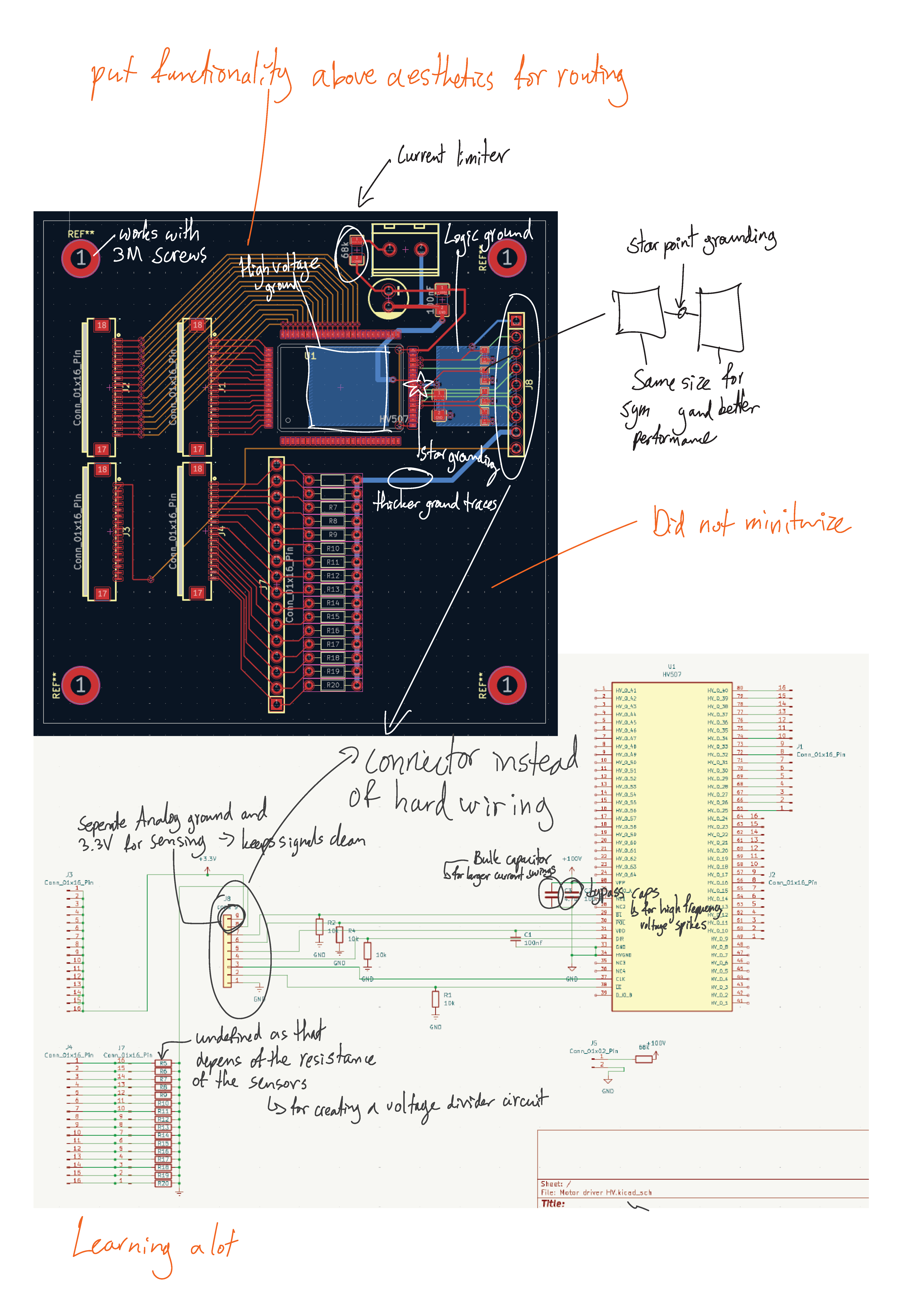

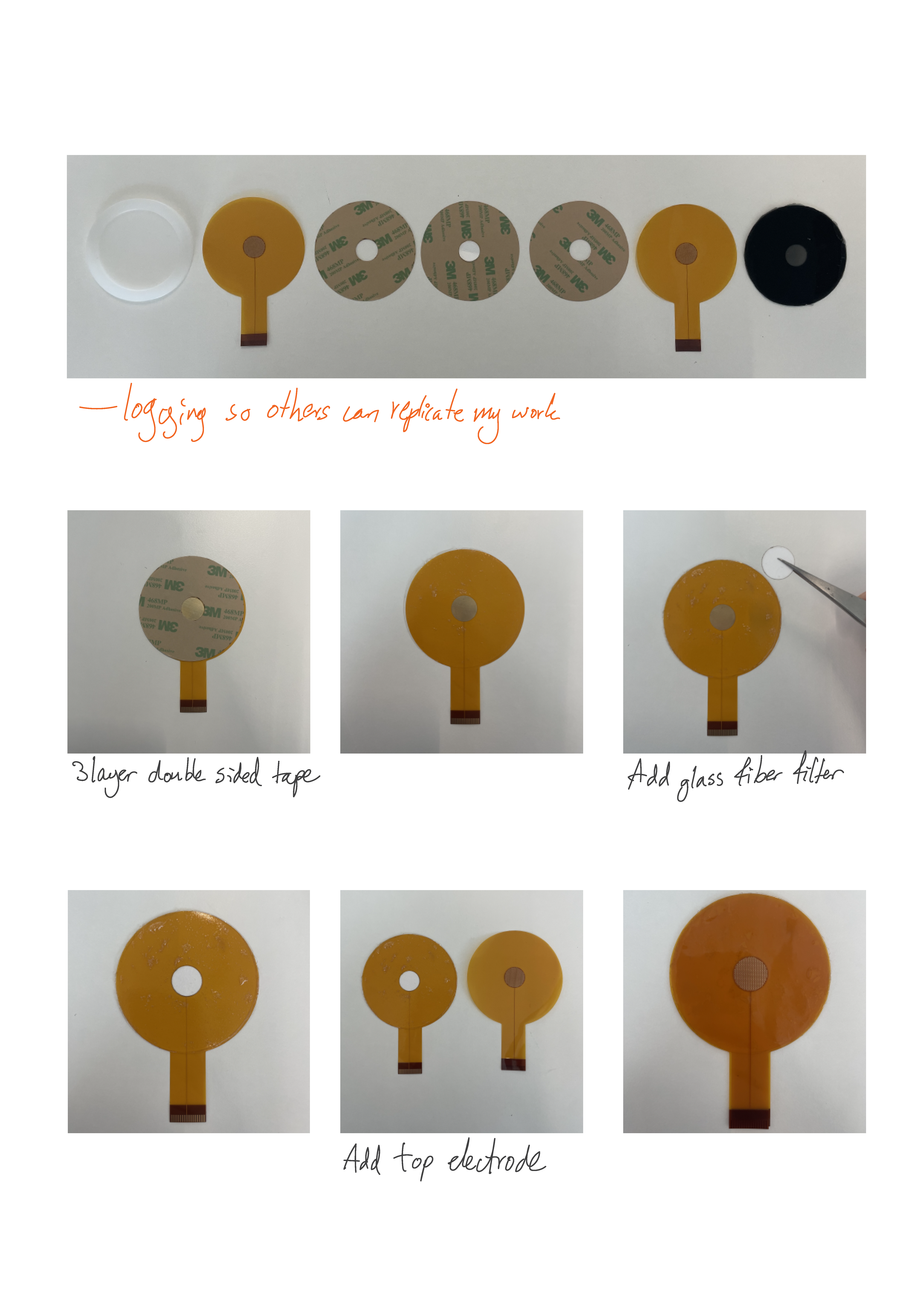

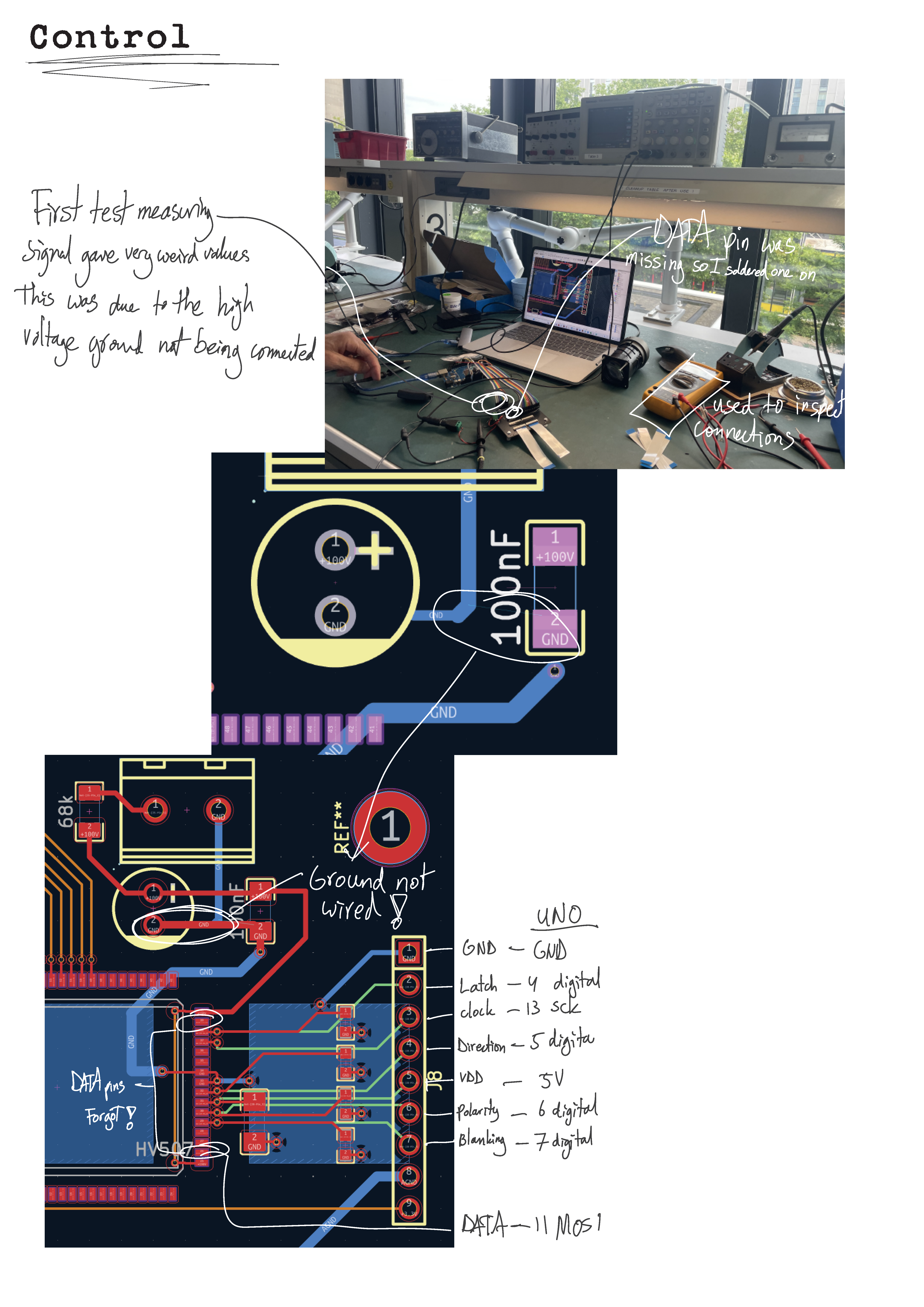

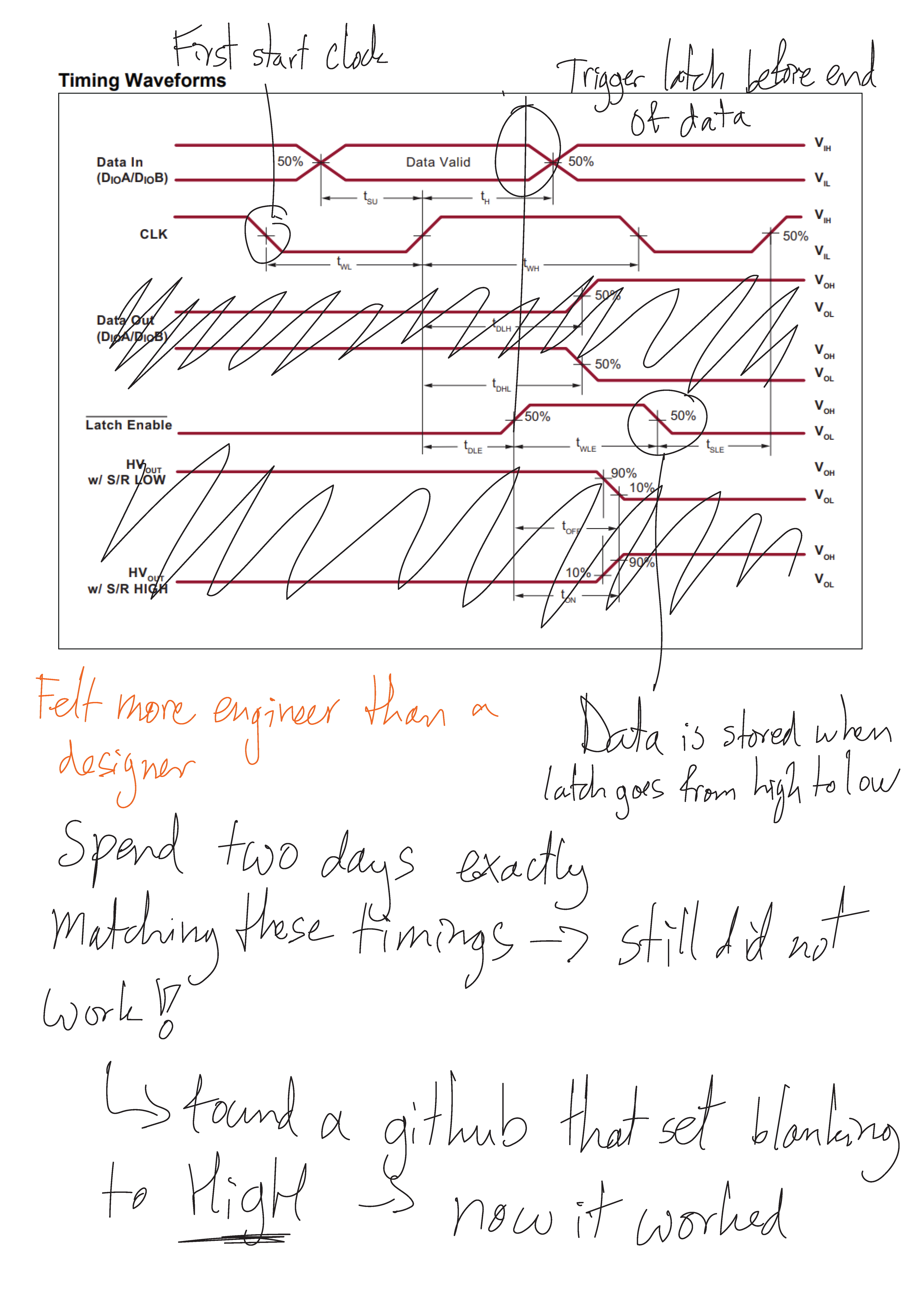

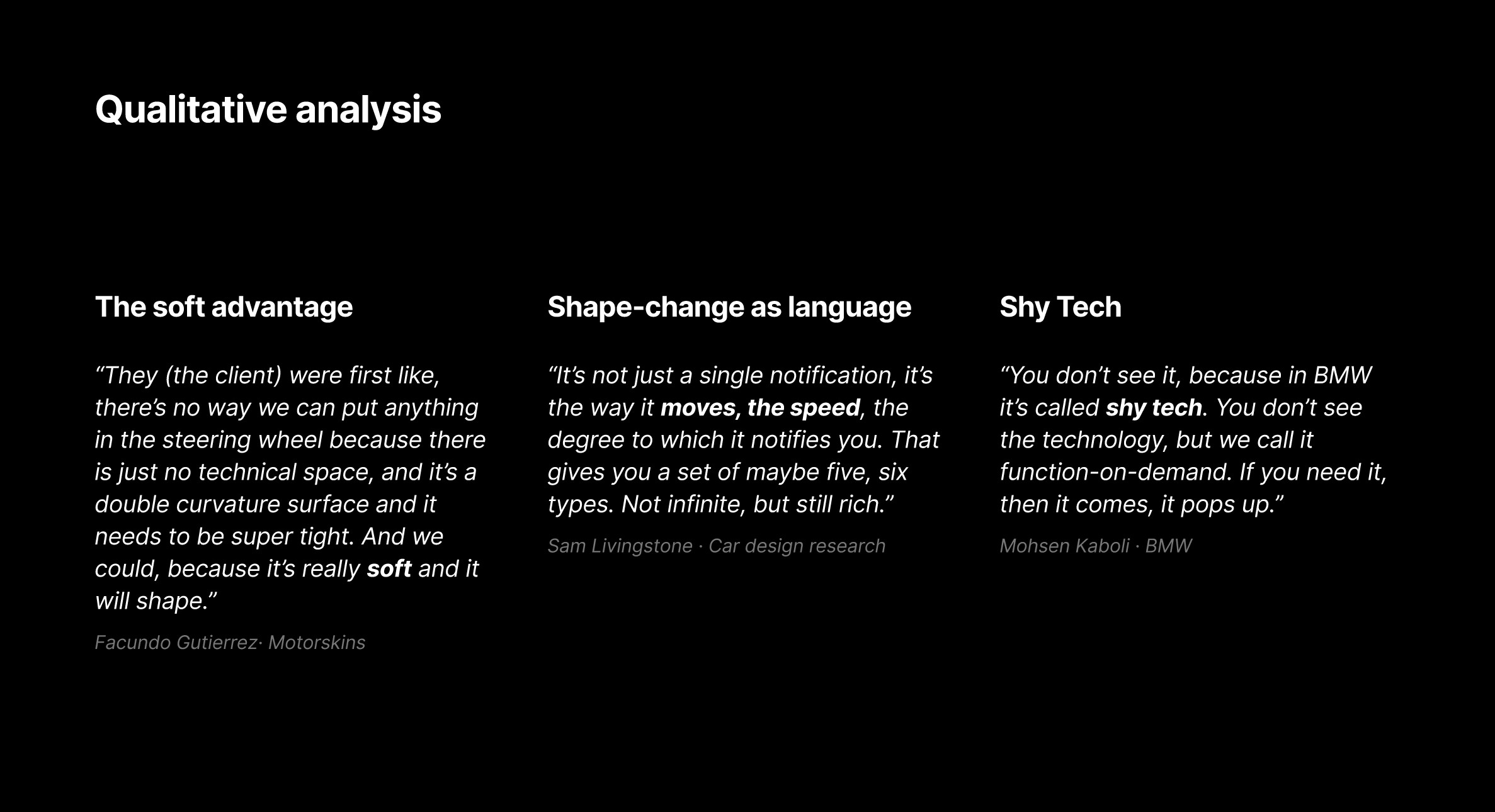

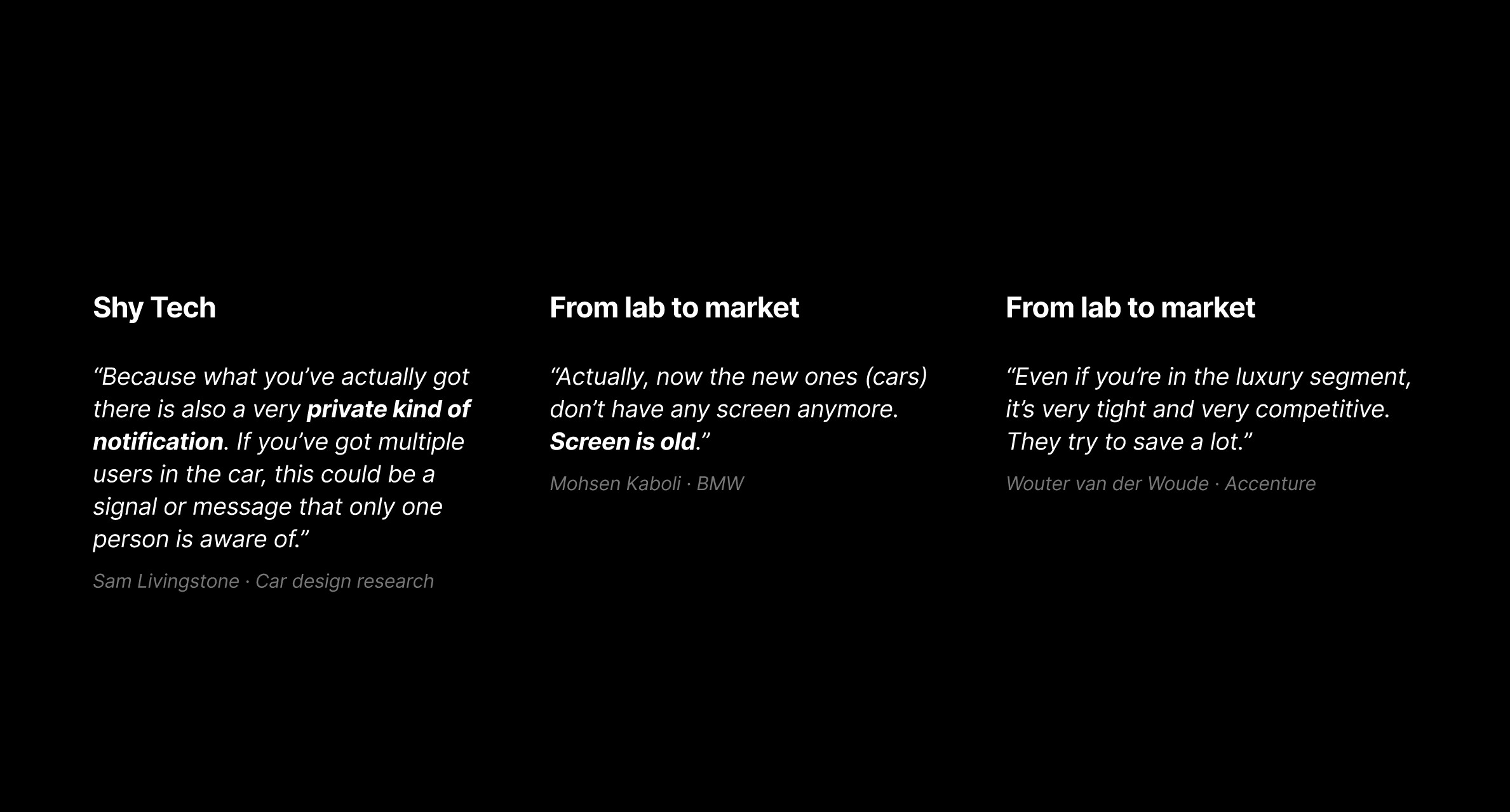

Rather than outsource the technical development or rely on speculative prototypes, I chose to build these pumps myself. As a designer, I believe knowledge comes through making, not just imagining how something could work, but physically engaging with materials, circuits, and failures. Throughout this process, I interviewed experts from BMW, Disney Research, Accenture, and research groups to position EOPs within a wider design and industry context. Rather than validating a novel actuator, this thesis explores how designers can actively shape its expression and use. It demonstrates how designers can engage directly with emerging technologies through physical prototyping, positioning design as a bridge between early-stage technological development and applied contexts in sectors such as soft robotics, automotive and entertainment.

Making logs (see all here)

Expert Interviews

Sensing

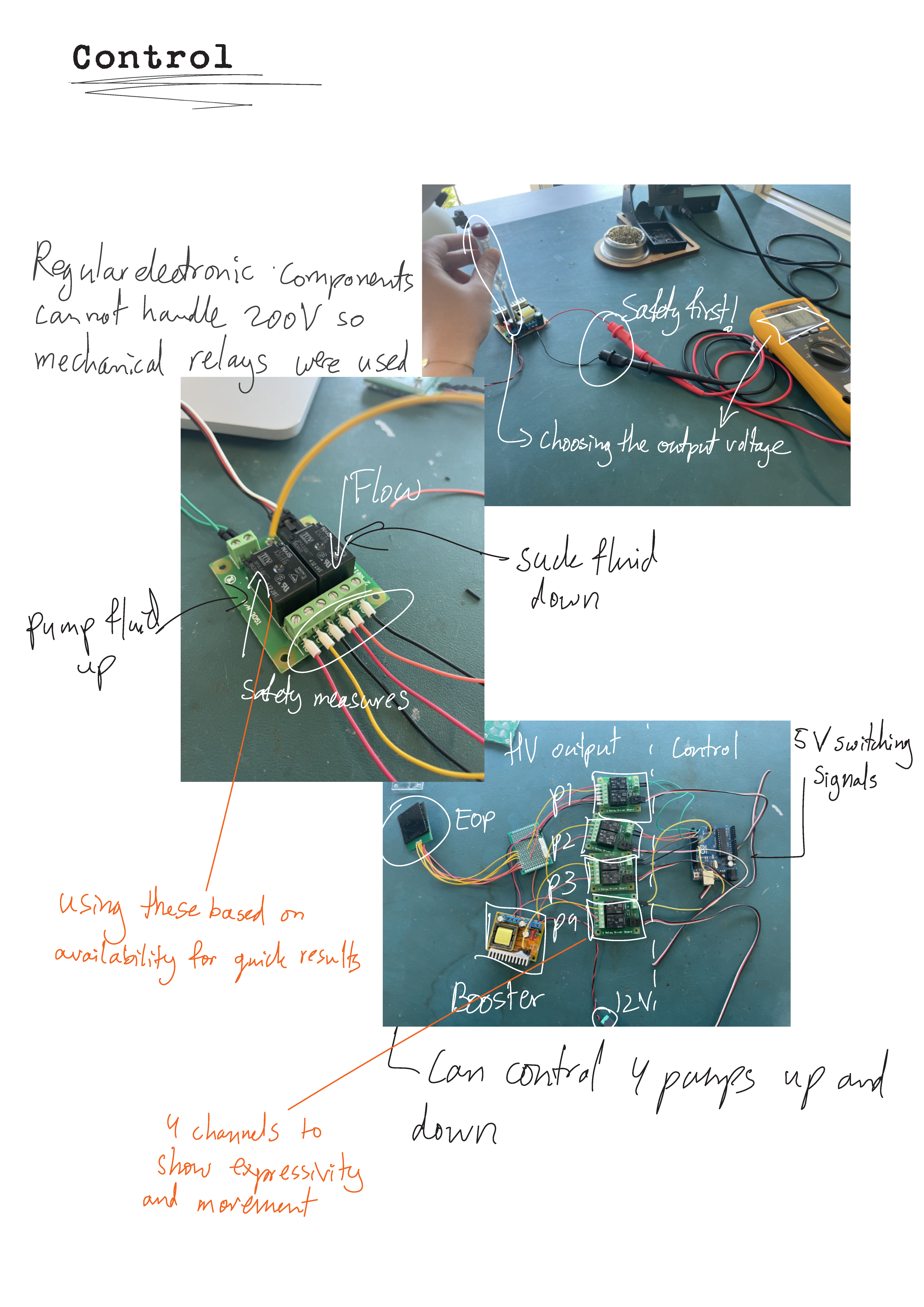

Final controls