VENTI toolkit

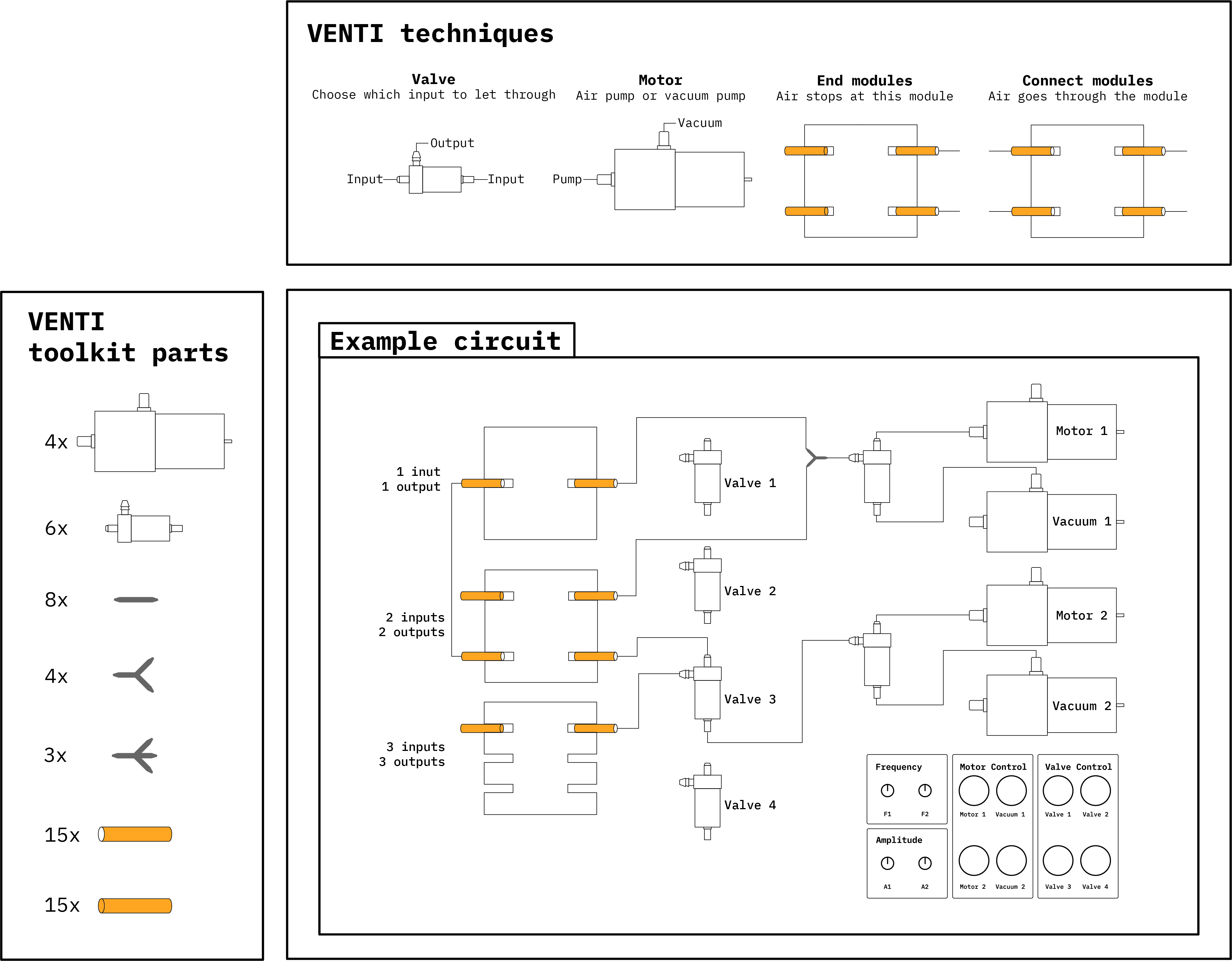

VENTI is a modular toolkit for real-time creation of pneumatic interactions and haptics, including inflatable modules with various textures and forms. Pneumatically actuated shape-changing interfaces can create unique functions and interactions, but technical expertise limits designers' ability to iterate rapidly. By connecting the inflatable modules and using the control panel to regulate air pressure, VENTI allows designers to manipulate air pumps and valves, enabling quick prototyping of complex pneumatic shape changes without specialized expertise.

Toolkit Overview

VENTI consists of three elements: soft pneumatic actuator modules, connectors, and a control panel. Seven different modules have been developed to offer a variety of shape-changes: two texture modules, two directional modules, two shape modules, and one layered module. Due to the modular design, every module can be combined with another module.

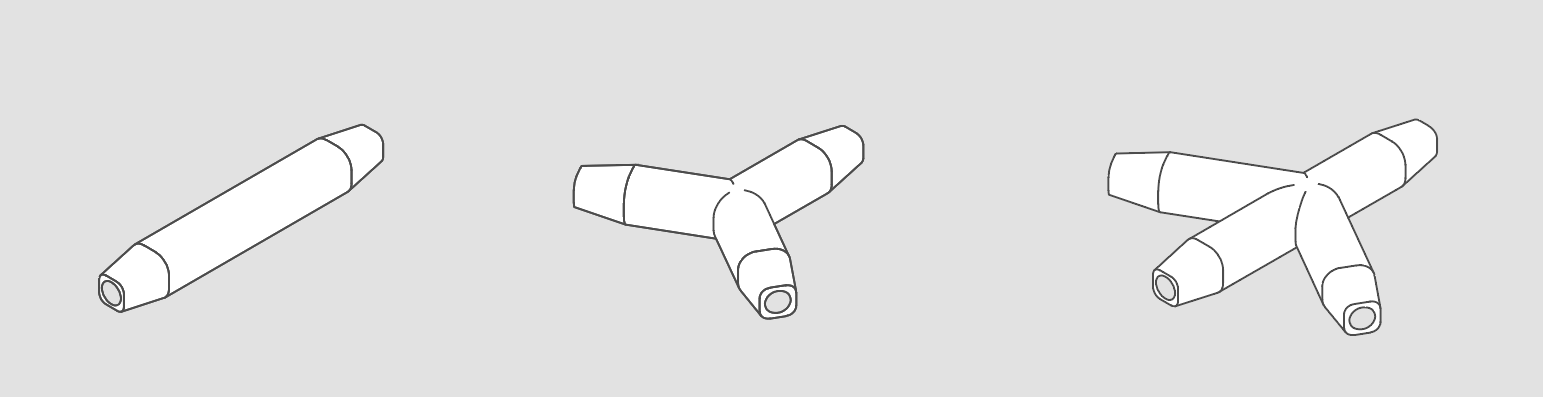

Messing rods are used to connect the modules with each other, and the solid messing rods are used to stop the airflow at the module you want. The clear tube connectors can be used to go from one to up to three different directions.

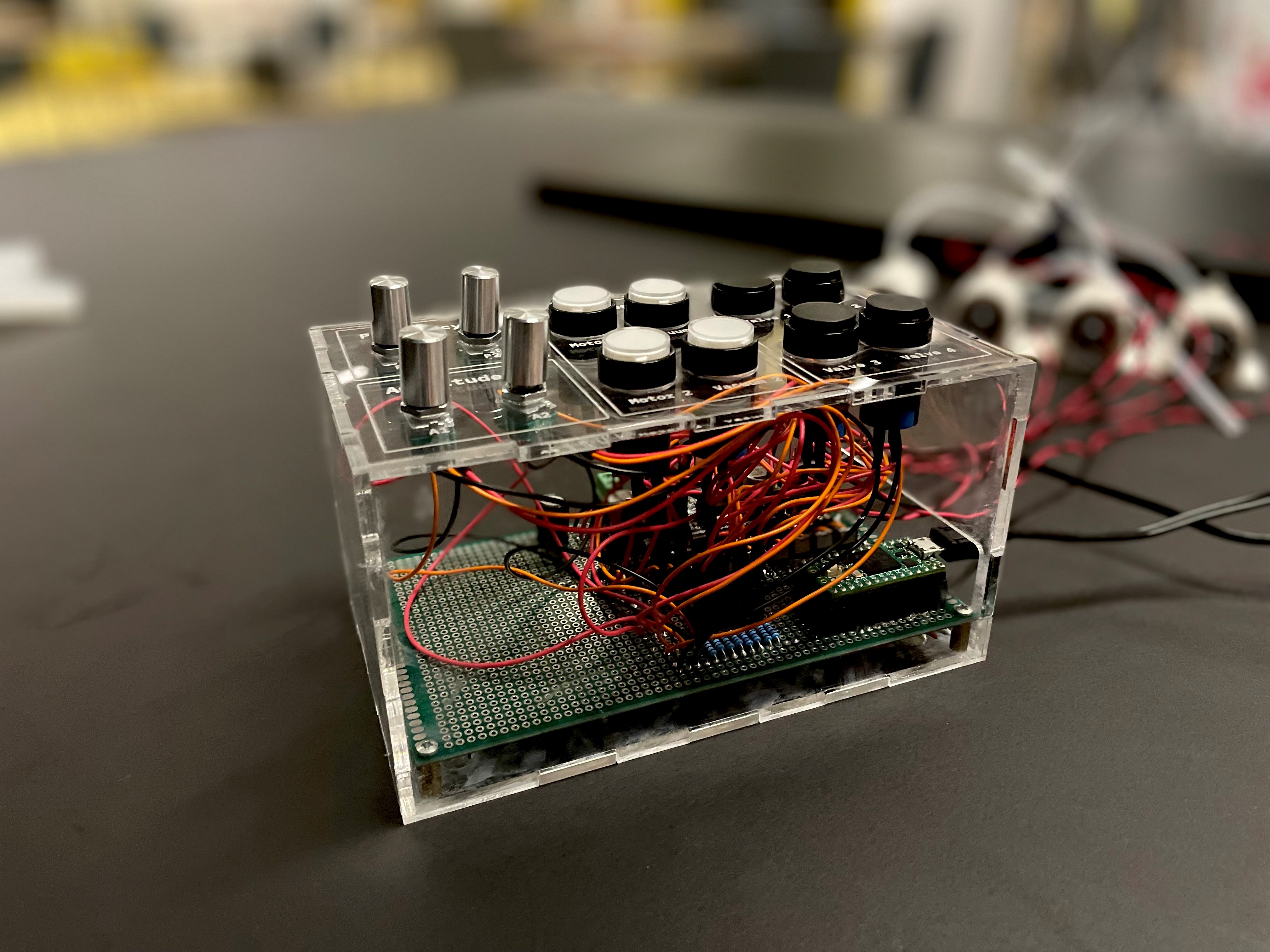

The control box has two modes: frequency mode and control mode. In frequency mode, users can control the amplitude and frequency of the airflow with the four potentiometers, enabling two different frequencies simultaneously. In control mode, users can press one of the four motor buttons to push or extract air from a module. The valve buttons can be used to switch between air inputs.

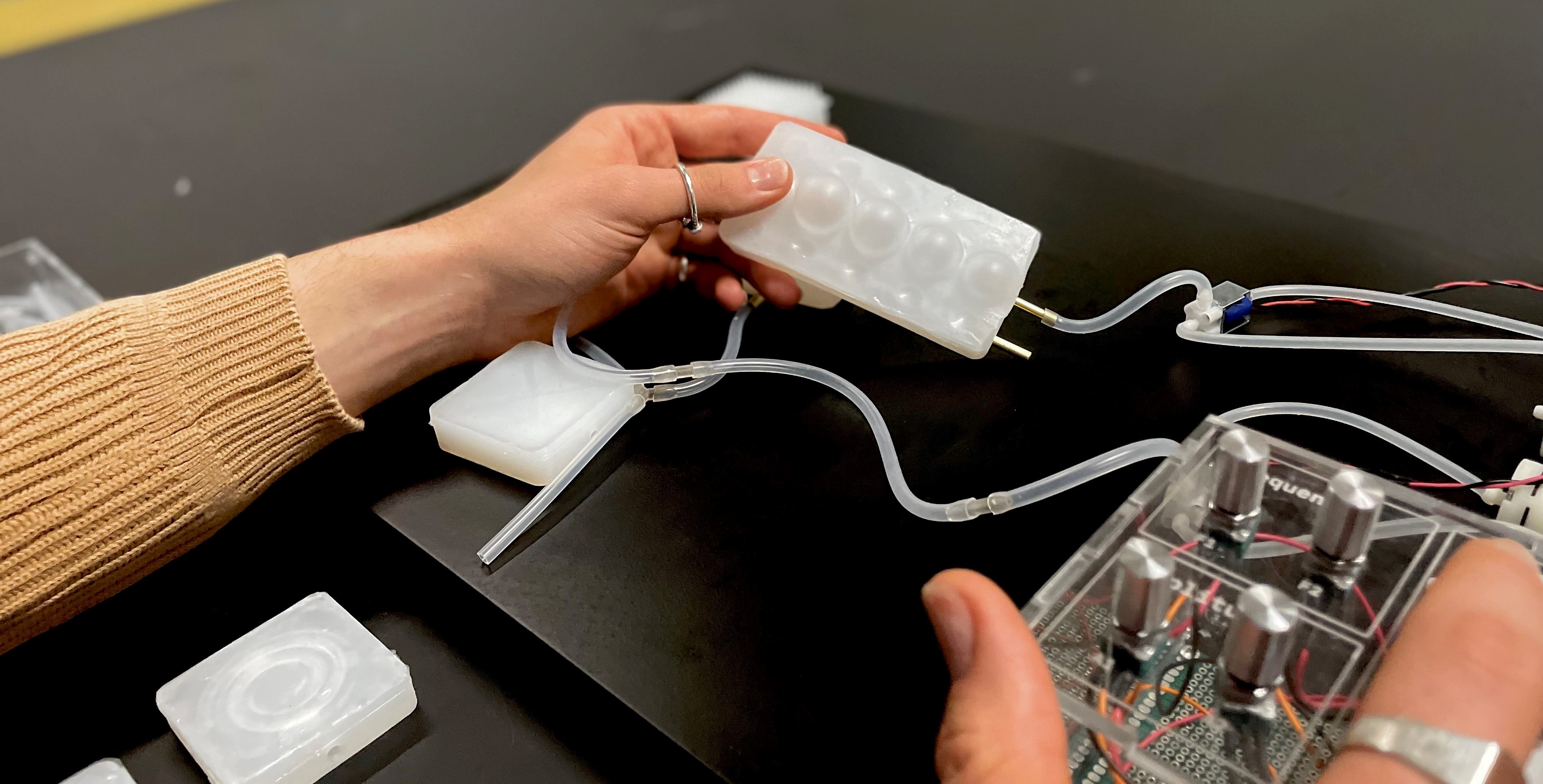

User using the toolkit

A user is able to control the inflatable modules while interacting and experiencing them. Instead of having to program behavior and then upload the code to see the result, VENTI allows for real-time exploration in motion patterns. In frequency mode, users can explore different frequencies — from fast-paced vibrations (~158 Hz) to slower, breathing-like patterns. In control mode, the user can add or subtract air by pressing buttons per channel. The valves ensure that this remains a closed system.

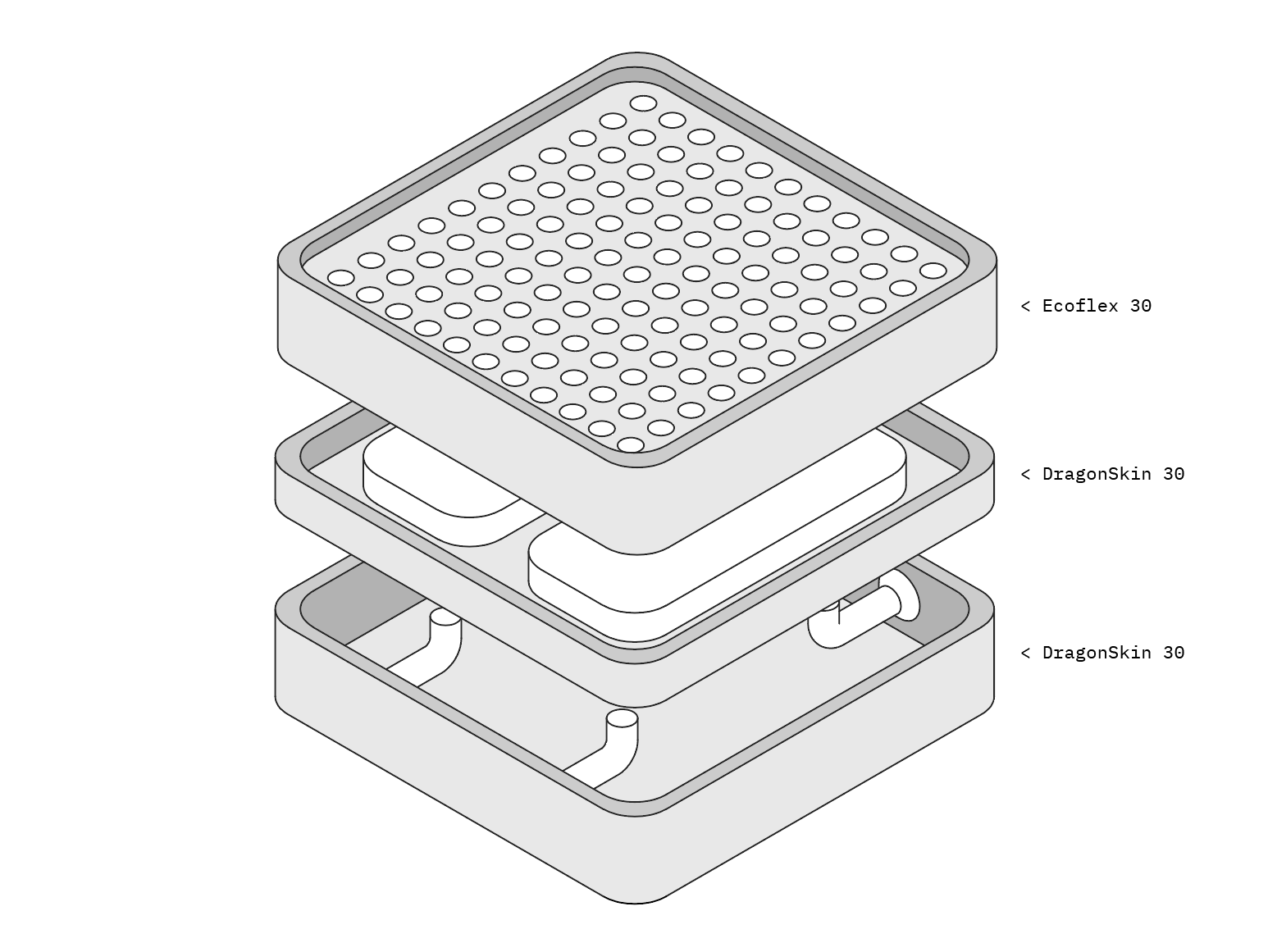

Module design

The bottom molds are made from Dragonskin 30, a harder silicone chosen to prevent ballooning when inflated. With a stiffer bottom, the modules stay in place. The bottom mold includes three input holes (3.5 mm) for air tubes, designed to ensure an airtight fit without excessive force. The wider tube ends assist in inserting the messing tubes. The mold is cured for two hours before removal, ensuring it holds shape while remaining flexible.

The top mold is made from Ecoflex 30, a soft silicone that is highly stretchable without tearing. It features openings for air entry and specific chambers that enable targeted inflation. After pouring silicone, the top mold cures for 4 hours before being glued to the bottom with more Ecoflex 30 for an airtight seal. The assembly sets for an additional 12 hours to ensure proper bonding.

Interactions

Demonstration

Connectors

To ensure airtight connections between the modules, clear SLA 3D printed connectors are used. These connectors have a rounded square shape to prevent the tubes from slipping off. The connectors have an inner diameter of 2 mm and are compatible with 2.5-4 mm silicon tubes.

The messing tube rods are 4mm and can easily be inserted into the modules for an airtight connection. This easy insertion allows for more exploration and a better experience while using VENTI.

Control box

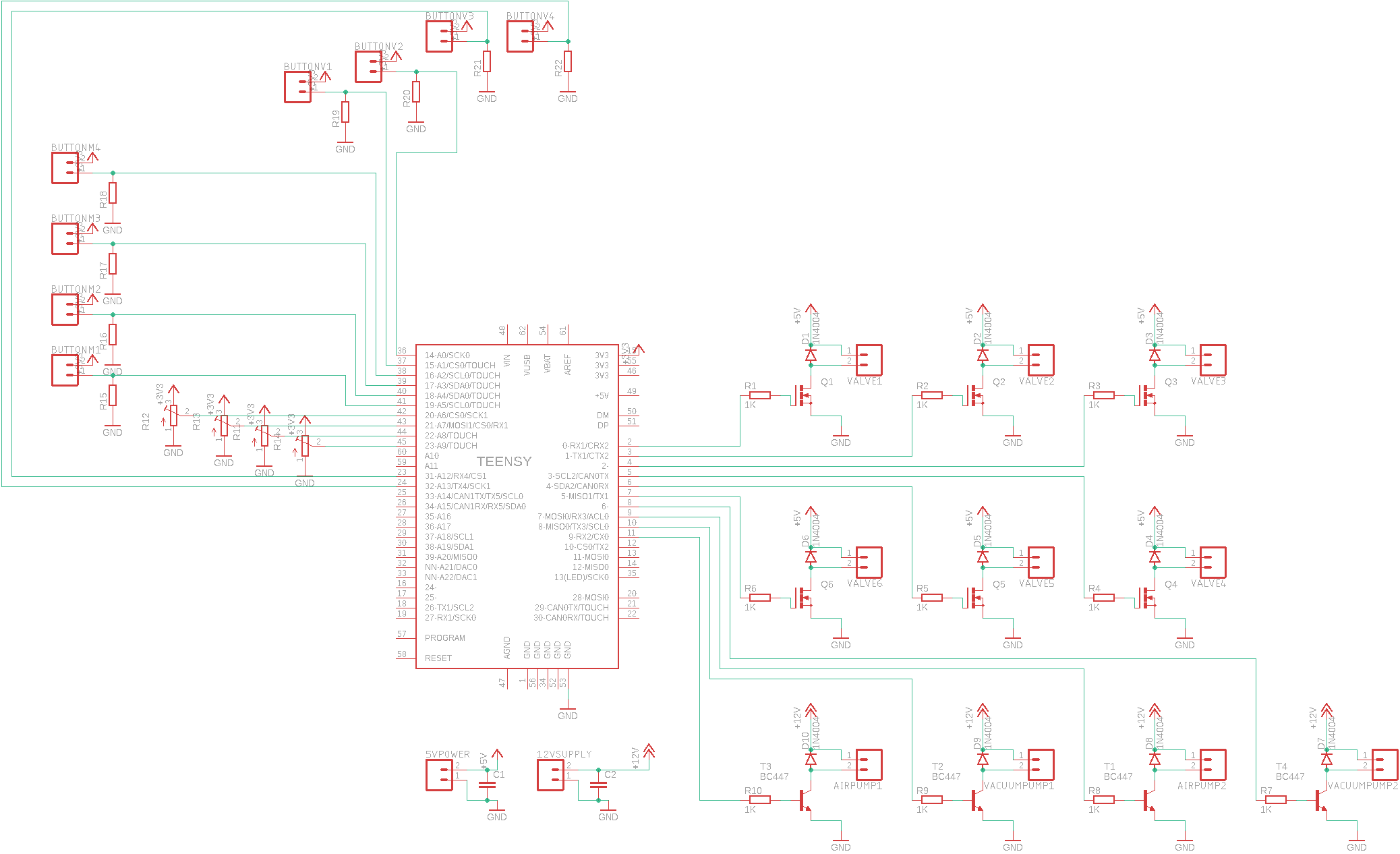

The control box features 4 potentiometers: 2 control the frequency of two channels, and 2 control the amplitude (airflow). The 4 motors are individually controllable via push buttons. Two valves are used to generate frequencies, while the remaining four valves can be controlled via black toggle buttons.

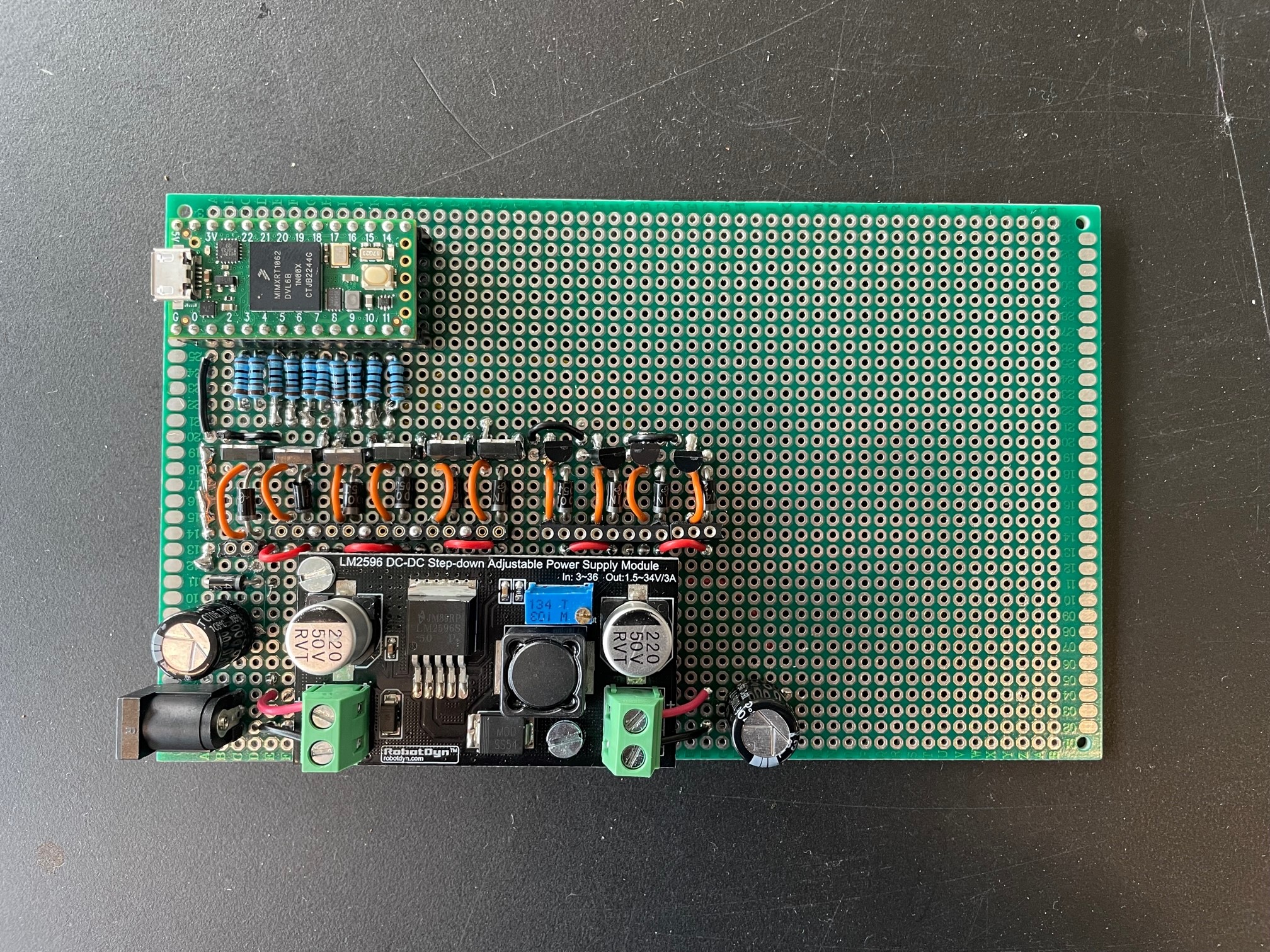

VENTI uses an LM2596 DC/DC converter to regulate voltages. The motors and valves are driven by n-channel FETs. A Teensy 4.0 is chosen as the microcontroller for its many PWM pins, essential for precise control.